Inventory Replenishment

Achieve the perfect balance of inventory, sales, and service levels with Manhattan Replenishment’s automated solution capabilities.

Contact Us

Keep Inventory, Sales, and Service at Ideal Levels

Evaluate Scenarios

Use what-if scenarios to evaluate alternative safety-stock strategies and service-level goals.

Optimize Space

Match orders to pack-size requirements to reduce handling costs and mitigate space constraints.

Plan Strategies

Simulate the impact of front-loading inventory during the preseason to intelligently plan restocking strategies.

Prevent Out-of-Stocks

Redistribute excess inventory to prevent emergency out-of-stocks.

Use Multiple Sources

Leverage multiple transfer sources when needs can’t be met by a single location.

Halt High-Risk Transfers

Prevent transfer of high-risk inventory nearing its spoilage date.

Seize Opportunity

Execute forward buys when financially favorable buying conditions arise.

Make Real-Time Evaluations

Enable on-the-fly evaluation of deal effectiveness.

Alter Promotions

Adjust overlapping promotional influences on expected demand.

Optimal Wholesale Replenishment

Ensure the best order-fill rates—with the least amount of inventory.

-

Customer-Centric Inventory

Manhattan’s inventory replenishment system allows for discrete analysis and demand forecasting for strategic customers.

-

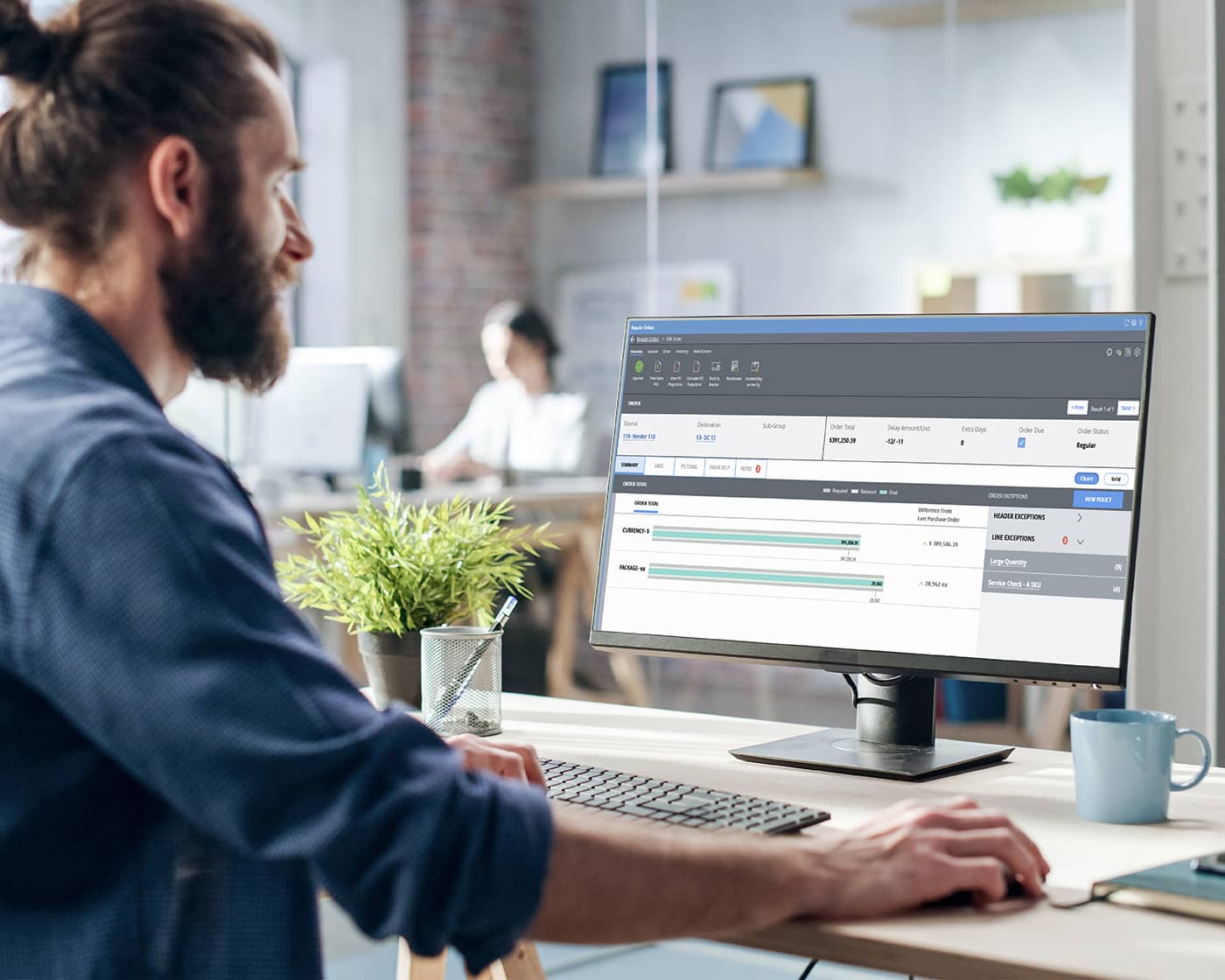

Automatic Replenishment

Inventory replenishment software allows you to know when, what, and how much to buy with guided workflows.

-

Ready to Grow

Helping complex wholesalers thrive—despite the industry’s low margins.

Optimal Retail Replenishment

Balance inventory investment across selling channels—while simultaneously expanding fulfillment.

-

Simulate Outcomes

Model inventory strategies to ensure maximum return on investment.

-

Improve Efficiency

Eliminate unnecessary inventory, reduce out-of-stock impacts, improve order-fill rates.

-

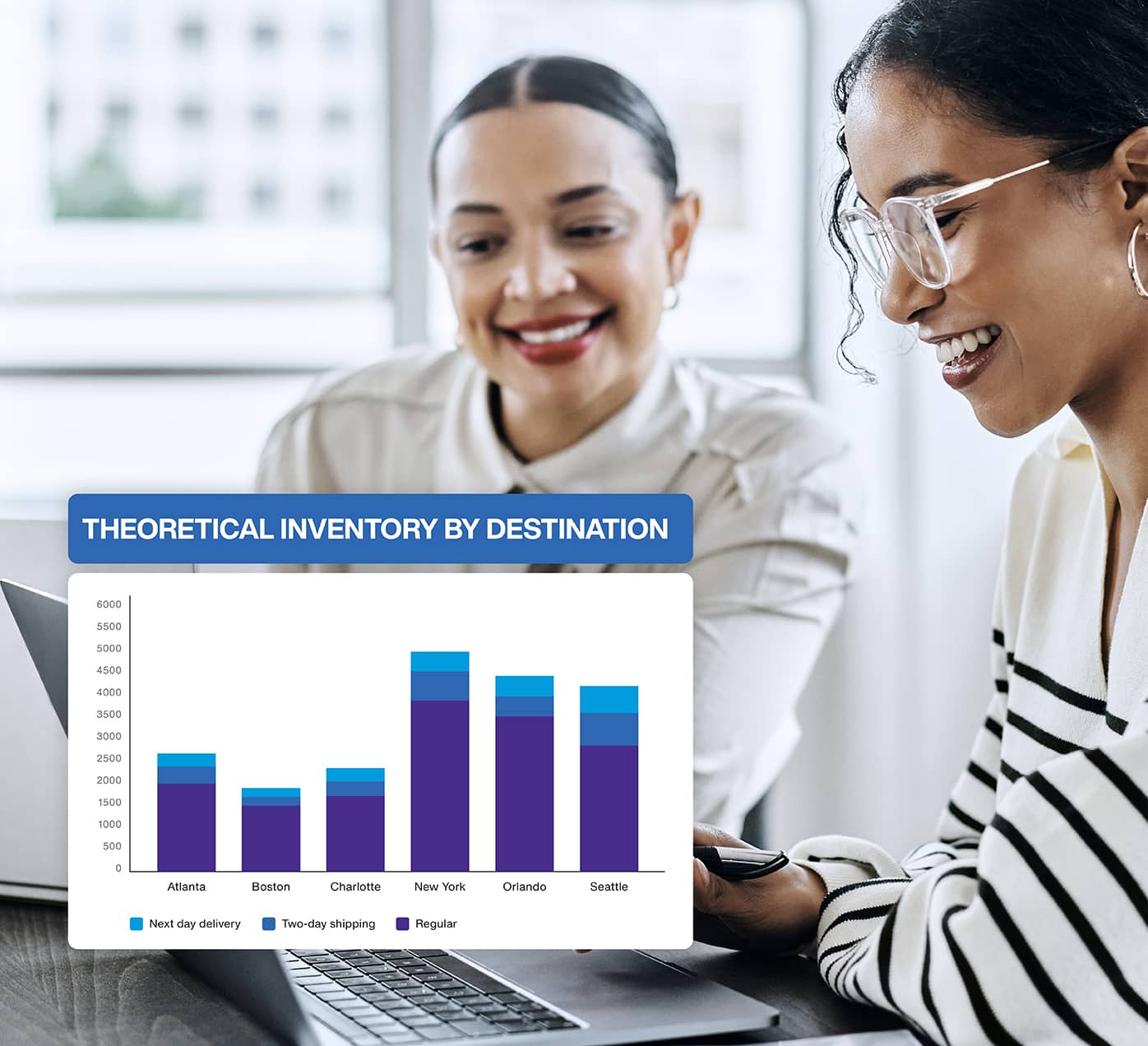

Use Data-Driven Insights

Leverage performance metrics and data visualizations to assess buying performance.

Manhattan Active® Platform

A cloud-native, evergreen, and extensible foundation engineered to handle the most complex supply chain networks in the world.

Composable Microservices

API-first architecture with automated scalability, resiliency, and availability. Every component is part of a shared application platform.

Innovation Independence

Our low code, no code, your code development strategy means you pick what method of configuration and customization works best for you—with as much support as you want or need.

Continuous Updates

Every 90 days, all Manhattan Active solutions automatically receive new features and enhancements.

KeHE takes fresh approach to replenishment

See how KeHE Distributors accomplished significant service-level improvements, as well as a 5% inventory reduction and 5% reduction in spoilage, with Manhattan Demand Forecasting and Replenishment.

Everything Works Better With Manhattan Solutions

Manhattan offers a complete breadth of solutions that when unified, provides total coverage for your supply chain commerce needs.

Warehouse Management

Control demand, supply, labor, and automation across your entire network with Manhattan Active® Warehouse Management.

Transportation Management

Manage every carrier, rate, route, and load with Manhattan Active® Transportation Management.

Point of Sale

Empower store associates with Manhattan Active® Point of Sale, a POS built to turn the store into an experiential showroom, customer service center, and neighborhood fulfillment point.

FAQs

What you’ll need to know about inventory replenishment software.

Also known as stock replenishment, inventory replenishment is the process of replacing the inventory that has been sold.

The five most-used methods are: manual replenishment, reorder point replenishment, automatic replenishment, demand-driven replenishment, and continuous replenishment.

Manual replenishment uses a human workforce to monitor inventory levels.

Reorder point replenishment sets a reorder point for each product, and automatically places an order when inventory drops below that level.

Automatic replenishment uses software to monitor inventory levels and place orders when inventory runs low.

Demand-driven replenishment uses sales data and forecasting to determine the optimal inventory and places orders based on this data.

Continuous replenishment is a collaborative operation between supplier and retailer; the supplier monitors retailer inventory and automatically replenishes if it drops below a certain level.

We support all methods: manual, reorder point, automatic, demand-driven, and continuous.

Replenishment replaces inventory that has been sold; allocation determines if inventory is in the right place at the right time.

Both focus on minimizing stock-outs and maximizing profits.

Contact Us

How Can We Help?

Talk with an expert to learn more about Manhattan’s technology.