Inventory allocation

Reduce product markdowns and stranded items by managing your short-lifecycle inventory more accurately with Manhattan Active® Allocation.

Contact us

The perfect distribution. Every time.

Logic tuning

Fine-tune the app to fit any business scenario.

Improved fulfilment

See, learn and adapt your highest-performing fulfilment strategies.

Adjustment simulations

Simulate inventory performance based on your allocation strategy.

Unified fulfilment

Include all store-based fulfilment of digital demands.

Unified performance monitoring

Monitor performance by channel—and adjust your allocation as needed.

Unified allocation optimisation

Get the best allocation over all channels—including stores.

Minimise price reduction

Fewer redirects, fewer end-of-season markdowns.

Decrease product expense

Less stranded inventory, lower financial risk.

Faster ROI

Lower cost of ownership plus faster return on investment.

Leverage AI and machine learning

Manhattan Active® Allocation leans into AI and machine learning to calculate your optimal allocation.

-

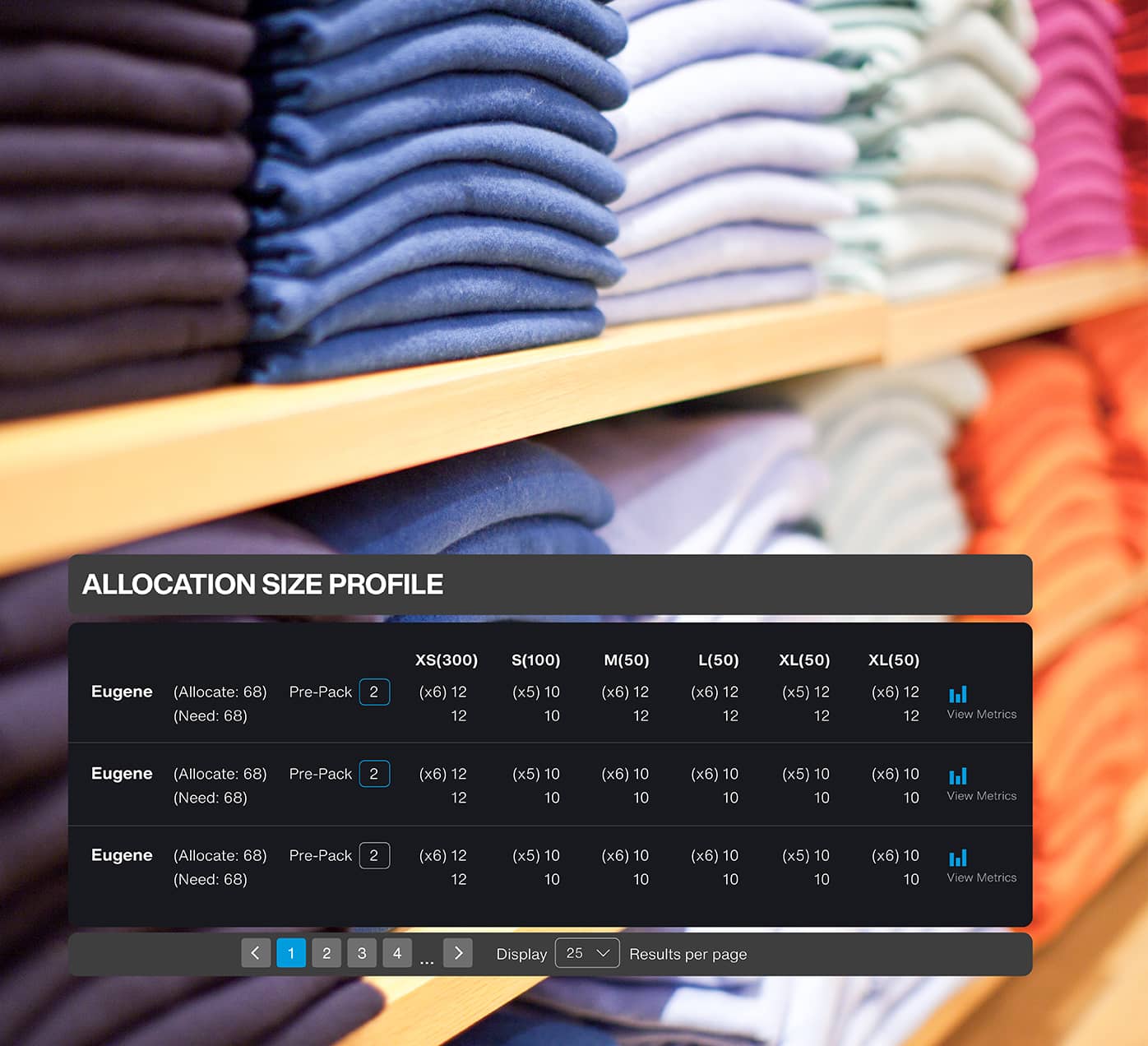

Understand what sizes sell

Size-optimisation algorithms help you align inventory with consumer demand.

-

Understand store clustering

Advanced machine learning groups inventory—all the way down to the store/style level.

-

Understand prepack selection

Retail allocation software selects the best prepacks based on expected demand patterns and size optimisation.

Meet demand across all channels

Access—and optimise—your entire network of inventory, demand patterns, traditional DC and store-based fulfilment.

-

Incorporate store-based fulfilment

Inventory distribution that factors in store-based fulfilment of digital demand.

-

See fulfilment impact

Segmentation of the impact of each store fulfilment on your inventory allocation.

-

Integrate with order management

Real-time integration—via microservice APIs—to any order management system.

Improve your demand forecasting

Gain a better predictive analysis—even for short-lifecycle products such as fashion.

-

Simplified modeling

Calculate the distinctive demand patterns of short-lifecycle merchandise.

-

Infused intelligence

When no demand history is available, machine learning identifies the demand patterns of similar items.

-

Dynamic feedback

Use embedded visual analytics to compare the forecast against actual sales.

Manhattan Active® Platform

A cloud-native, evergreen and extensible foundation engineered to handle the most complex supply chain networks in the world.

Composable microservices

API-first architecture with automated scalability, resiliency and availability. Every component is part of a shared application platform.

Innovation independence

Our low code, no code, your code development strategy means you pick what method of configuration and customisation works best for you—with as much support as you want or need.

Continuous updates

Every 90 days, all Manhattan Active solutions automatically receive new features and enhancements.

Everything works better with Manhattan solutions

Manhattan offers a complete breadth of solutions that when unified, provides total coverage for your supply chain commerce needs.

Warehouse management

Control demand, supply, labour and automation across your entire network with Manhattan Active® Warehouse Management.

Transportation management

Manage every carrier, rate, route and load with Manhattan Active® Transportation Management.

Point of sale

Empower store associates with Manhattan Active® Point of Sale, a POS built to turn the store into an experiential showroom, customer service centre and neighbourhood fulfilment point.

FAQs

What you’ll need to know about Allocation apps.

Matching available inventory to customer orders.

Allocation constantly balances high-priority orders against the need to minimise both stockouts and excess inventory.

Machine learning enables more efficient allocation.

Here’s why: Machine learning is able to handle the volume of data and increasing complexity involved in allocation. It is able to analyse huge amounts of data from multiple sources—including historical sales data, customer demand patterns and inventory levels—then identify trends and make more accurate predictions.

Using some—or all—of these factors, allocators can reduce both overstocks and stockouts:

- Accurate demand forecasting—for a clear understanding of customer demand patterns.

- Real-time visibility—to see up-to-date information about inventory levels.

- Flexibility—to respond to changes in demand and adjust allocation accordingly.

- Integration—with other systems, such as order management, shipping and accounting.

- Automation—for routine tasks, such as inventory tracking and reporting.

- Scalable systems—to handle fluctuating volumes of data.

- Data security—to protect sensitive business data, such as inventory levels and customer information.

Manhattan Active Inventory was engineered specifically for short-lifecycle planning.

It’s cloud-native, evergreen, extensible—and never needs upgrading.

Meet our partners

We deliver added value through partnerships with these best-in-class vendors.

Contact Us

How Can We Help?

Talk with an expert to learn more about Manhattan’s technology.