What is Supply Chain Transformation?

Supply chain management is a critical business function in many industries. Leaders working with legacy systems often struggle to respond to supply chain disruptions or shifting consumer demands. However, supply chain transformation helps leaders make data-driven decisions about inventory and the supply chain, improve their efficiency, and more accurately manage risks.

What is Supply Chain Transformation?

Key Takeaways

- Supply chain transformation offers several benefits, including increased scalability and agility and improved risk management.

- Before transforming your supply chain, it's best practice to assess your existing processes, develop a roadmap, and apply careful change management.

- Siloed projects and poor data governance are common challenges with supply chain transformation.

- AI, Machine Learning, and IoT/edge computing are going to play an important role in the evolution of supply chains in the coming years.

- Cloud-based solutions for supply chain management offer a way for organizations to stay agile and benefit from economies of scale.

Supply Chain Transformation Defined

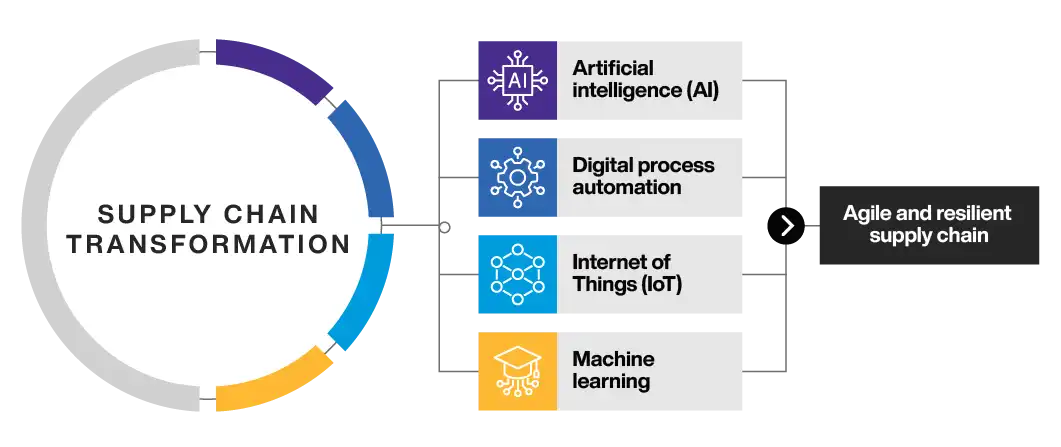

Supply chain transformation refers to using digital technology, such as artificial intelligence (AI), digital process automation, Internet of Things (IoT), and machine learning, to carry out supply chain tasks with minimal human intervention, creating an agile and resilient supply chain. The practice can streamline inventory management, enabling businesses to scale up their operations efficiently while minimizing costs.

Modern supply chains are complex, and several external factors can disrupt them, including pandemics, shipping disruptions, labor shortages, and geopolitical instability. Sophisticated consumers expect to be able to purchase goods and services and have them delivered promptly, no matter where they're coming from. Delays and missing items aren't tolerated.

Supply chain automation tools offer real-time insights into inventory management and remove bottlenecks in areas such as inventory management and document processing. Organizations that adopt these strategies become more flexible, agile, and resilient.

To remain competitive in an industry with demanding consumers and thin margins, organizations must look for ways to make their supply chains more flexible and reliable. The Engineer reports that between Q1 2022 and Q1 2024, there was a 320% increase in the deployment of autonomous robots. This trend is set to continue as businesses worldwide look to take advantage of the benefits automation offers.

What are the Key Drivers of Supply Chain Transformation?

The main drivers of supply chain transformation vary between organizations. However, it's typically rooted in both customer demand and a need for flexibility and scalability. Key drivers of transformation in the supply chain include:

- Increasing customer sophistication. Customers want fast, reliable service and omnichannel fulfillment. A flexible and reliable supply chain is key to improving customer service.

- Labor shortages. The Center for Global Development, Organization for Economic Co-Operation and Development, predicts that by 2050, more than 92 million working-age people will be lost from the workforce, with a gain of more than 100 million elderly individuals. Countries in the OECD alone will require an additional 15 million workers per year to meet their basic needs. Automation can reduce the strain on the workforce.

- Geopolitical instability. The economic risk of climate change is projected to be around $81 billion. Pandemics and geopolitical instability also present challenges to global trade. Supply chain transformation helps organizations respond dynamically to changing global environments.

- Sustainability and ESG Requirements. Regulatory requirements, such as the US Uyghur Forced Labor Prevention Act and the German Supply Chain Due Diligence Act, require companies to monitor their supply chains closely. Shifting consumer preferences also put commercial pressure on organizations to emphasize Environmental, Social, and Governance (ESG) policies.

- Data and Machine Learning Trends. AI and machine learning have put supply chain management within reach of many more organizations. Early adopters of AI technologies report a 35% decrease in inventory levels, a 15% reduction in logistics costs, and a 65% improvement in service levels.

Pillars of a Modern Supply Chain Transformation Strategy

There are four key pillars that form the core of an effective supply chain transformation strategy:

1. Data-Driven Decision Making

Real-time visibility into your supply chain enhances efficiency, helps reduce costs, and improves customer satisfaction. It also facilitates data-driven decision-making, supporting demand sensing and demand shaping.

By providing insights into inventory levels, production schedules, shipments, and warehouse data, supply chain visibility tools help organizations identify bottlenecks and respond to changing levels of demand.

2. Advanced Technologies

A key difference between modern supply chains and legacy systems is the amount of available data and the way data can be shared and utilized. IoT devices and edge computing support the tracking of inventory and shipments at every stage. Cloud-based orchestration can span the entire business, supporting all aspects of your operations.

AI and Machine Learning provide real-time forecasts based on data from your WMS/POS systems and other tools.

3. Unified Planning and Execution

Achieving the goals of your S&OP or IBP becomes easier when your supply, distribution, and transportation operations are working in unison. Supply chain transformation breaks down silos and maximizes efficiency at each stage of the chain.

4. Agility & Resilience

Modern supply chain automation solutions help organizations take advantage of distributed fulfillment, reducing their vulnerability to disruptions in any given area. They also simplify scenario planning, helping leaders identify and mitigate risks to their operations and respond more decisively and promptly to shifting conditions.

The Transformation Journey: From Strategy to Execution

To ensure a smooth rollout of supply chain tools and new processes, it's important to follow a systematic process and have a clear understanding of your existing systems and long-term goals.

Maturity Models: Where Are You Now?

For each of the supply chain maturity models (Procurement, S&OP, Processes, etc), consider where your organization currently sits. Carry out a detailed assessment: What are your strengths and weaknesses? Can you preserve your current strengths while modernizing and improving your operations?

Building a Case for Supply Chain Transformation

Stakeholder buy-in is an essential part of change management. Before you start working on supply chain transformation, meet with process owners at each stage of the chain, and understand their needs and challenges. Use this information to build a business case.

Design and Implementation

Once you've put together a strong business case, follow the supply chain transformation playbook:

- Assess your current operations.

- Align processes and operations with your S&OP / IPB.

- Pilot the new processes and review/revise changes as necessary.

- Scale the new systems to cover your whole organization.

Navigating the Transition

Change management processes can help you assess your organizational readiness and navigate the practical and human elements of the transition. In the rush to see cost savings and efficiency improvements, change management is often neglected. However, a study by Prosci found that 88% of projects with robust change management practices were able to achieve or surpass their targets.

Technology as an Enabler, Not a Silver Bullet

Modern supply chain platforms such as Manhattan's supply chain execution, omnichannel and supply chain planning solutions offer visibility into your entire supply chain, unifying distribution, labor, automation, and transportation.

Utilizing an end-to-end solution instead of attempting to address pain points individually provides a foundation for long-term resilience and scalability. While it can be tempting to look for quick wins and short-term optimizations, poorly integrated solutions can create new challenges, reducing your agility and making scaling a challenge.

Common Pitfalls and How to Avoid Them

Any digital transformation project carries some risk, and major changes to a supply chain are no exception. Look out for these common pitfalls when planning a supply chain transformation.

Siloed Initiatives Without Executive Sponsorship

A project without an executive sponsor is like a ship without a captain, and a project championed by just one small team or department could be missing the big picture. Bring in expertise from as many functional areas as possible to plan and implement your supply chain transformation.

Lack of Data Governance

A lack of data governance, or inadequate policies, presents a huge risk to any business. The most extreme consequences of poor data governance come in the form of regulatory penalties or data breaches. However, there can be other side effects that take longer to notice, but still harm your business.

The presence of data silos can create bottlenecks and lead to inaccurate data, causing a loss of customer trust. Scaling operations when data is siloed, outdated, and recorded in inconsistent formats is difficult, and undoing these issues requires significant time investment.

Underestimating Change Management

A supply chain transformation project doesn't end once the software is installed and the processes are documented. Pilot programs, stakeholder advocates, and extensive training are all important parts of digital transformation.

Case Studies & Success Stories

DHL Moves to Cloud-First

International logistics company DHL embraced a cloud-first supply chain strategy with Manhattan ActiveÒ Warehouse Management (WM). The company has around 14 million square meters of warehouse space and was struggling to manage it with on-premises supply chain solutions.

Working with Manhattan, DHL implemented versionless cloud software, reducing the costs of maintaining their supply chain solutions. The logistics company plans to bring hundreds of sites on board, deploying autonomous robots to improve productivity at the same time.

Costa Logistics Centralizes Its Operations

Third-party warehousing and distribution company Costa Logistics partnered with Manhattan to improve the day-to-day operations of its warehouses. The company wanted to shift away from a decentralized software model to gain more control over its sites.

Since implementing Manhattan Active WM, Costa Logistics has seen its cost per case fall by 10% and its pick rate improved by 10%.

Crete Carrier Reinvents Its Operations

Crete Carrier is one of the largest privately owned trucking operations in the United States. It has more than 3,900 tractors and 9,600 trailers. Shaffer Trucking, one of Crete's divisions, transports food and other temperature-sensitive products, making speed and efficiency paramount.

The company was struggling with wasted hours, compliance challenges, and unproductive trips. Partnering with Manhattan, the company reduced wasted hours by 8%, increased its truck production, and reduced deadhead percentage by making better dispatch decisions and improving its driver management.

What’s Next? Future Trends in Supply Chain Transformation

Supply chain transformation is continuously evolving. Some trends to look out for in the next few years include:

Digital Twins and Carbon Neutral Supply Chains

In the next few years, we're likely to see increased use of simulations and digital twins to model the interaction between various elements of the supply chain. These simulations can not only improve operational efficiency but also support carbon-aware supply chain decision-making.

Generative AI

Generative AI could be the missing link that bridges the gap between legacy and intelligent supply chains. Accenture Research predicts that Generative AI could impact 43% of end-to-end supply chain activities.

Autonomous Fulfillment and Delivery

In 2023, the global autonomous last-mile delivery market was valued at $18.7%. This figure is expected to reach $144.2 billion by 2033. Autonomous fulfillment could help alleviate labor shortages and reduce greenhouse gas emissions by improving the efficiency of the last mile.

Making Transformation Real

Rising consumer demands and increasingly challenging market conditions mean organizations must find efficiency improvements anywhere they can. Those who fail to invest in making their supply chains more resilient risk being left behind by their competitors or facing significant business disruption.

Supply chain transformation is an ongoing journey rather than a one-off project. It requires regular evaluation and refinement, and it impacts all aspects of your business.

Manhattan's supply chain execution and planning solutions cover all aspects of your operations, including:

We also provide solutions for Point of Sale (POS) systems and omnichannel commerce. Our cloud-based solutions remove the challenges of maintaining on-premises solutions, giving you a unified view of your operations while simultaneously improving your agility. Since 2010, Manhattan has invested more than one billion dollars into research and development, enabling us to leverage emerging technologies to improve supply chain operations.

Learn more about Manhattan and how we can help you secure your position as a market leader in your industry, or contact us now to book a consultation.

AI Conversation on Supply Chain Transformation

Unpack the Surging Need for Unified Supply Chain Planning

Explore the only solution on a microservice API, cloud-native platform, that simplifies planning by unifying demand forecasting, replenishment, and allocation.

Demand Forecasting

A hybrid approach to forecasting that seamlessly blends the power of proven statistical models with cutting-edge AI.

Replenishment

Seamlessly integrates AI-driven insights with real-time data to autonomously optimize inventory levels across all channels, ensuring the right products are always in the right place at the right time, without the need for manual intervention.

Allocation

Maximize sales opportunities, minimize stockouts, and optimize inventory across all locations and channels with unparalleled precision. Powered by cutting-edge AI and machine learning, our solution ensures your products are always in the right place at the right time.

Bridging the Gap Between Supply Chain Planning and Execution

Learn how supply chain transformation helps businesses become more resilient and respond to challenging market conditions, thanks to real-time business insights.

Related Articles

Beyond Traditional Forecasting: The Hybrid AI Advantage

Revolutionize your supply chain with Hybrid AI Demand Forecasting by Manhattan’s UFM.ai. Tackle demand volatility, optimize inventory, and enhance global accuracy.

Learn MoreThe Game-Changing Power of Manhattan Active® Supply Chain Planning

Discover the game-changing power of innovative supply chain solutions. Learn how technology-driven strategies enhance efficiency, agility, and business growth.

Learn More