What is a Transportation Management System?

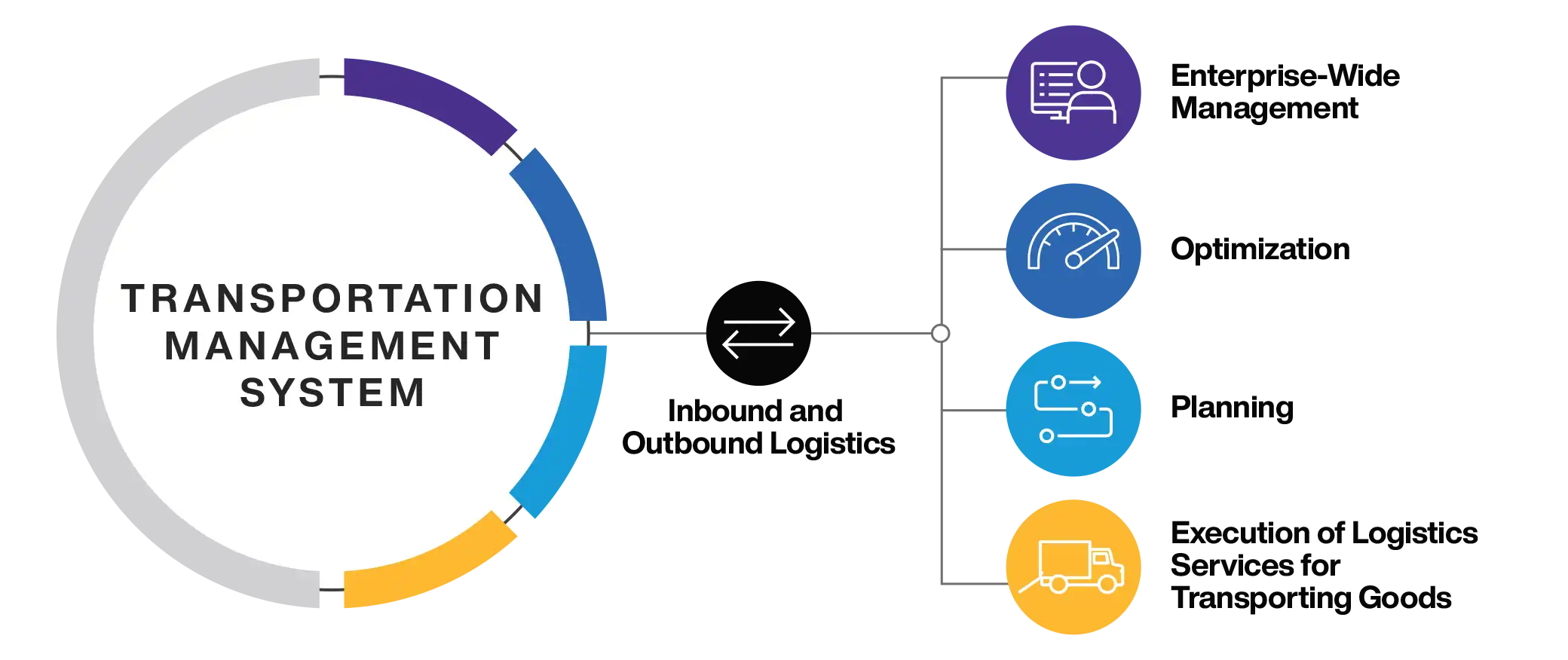

A Transportation Management System (TMS) is a crucial supply chain software solution that facilitates comprehensive management, optimization, planning, and execution of logistics

and transport services. This technology streamlines the movement of goods, enhancing efficiency and coordination for both inbound and outbound transportation. Read more to find out what a TMS is, key functionalities and challenges, and everything else you need to know about TMS.

What is a Transportation Management System?

What is Transportation Management?

Transportation management controls and oversees the movement of products or goods throughout an organization’s supply chain network, ensuring the methods of transport are running at peak efficiency. Having modern transportation management capabilities that are unified and connected with other supply chain solutions and built to adapt to supply chain disruptions — including fluctuations in customer demand and rising shipping rates — is imperative in today’s market (especially in a world rapidly shifting toward direct-to-consumer omnichannel fulfillment methods).

Today’s transportation management must be able to modify last-minute adjustments or cancellations customers make to their order, get the most out of each volume of shipment by maximizing capacity, and optimize shipment routes to ensure product is delivered as quickly and cost-effectively as possible.

What is a TMS and Why is it Important?

A transportation management system (TMS) is a supply chain software solution that enables enterprise-wide management, optimization, planning, and execution of logistics services for transporting goods in both inbound and outbound movement. TMS plays a vital role in a supply chain technology ecosystem as it optimizes the movement of goods from point A (often a distribution center or warehouse) to point B (often a retail store location or the point of sale to the buyer/end customer).

Transportation management within a supply chain network can provide challenges for businesses to address in order to ensure profitability and efficiency. Rising fuel and carrier costs, lack of network visibility, and inefficient processes within transportation management can cause significant losses to overall business productivity. Organizations without the proper TMS software capabilities can be left behind in a competitive modern supply chain industry where customers expect fast results.

Modern transportation management systems solve the previously mentioned challenges with beneficial technology capabilities. The key benefits users gain from TMS include:

- Optimization of routes traveled and carrier loads

- Real-time visibility of an entire transportation network

- Coordination of fleets by balancing and allocating resources

- Automation that provides compliance assurance, cost reduction, and increased efficiency

- Improved planning

All of which effectively increase profitability and improve customer satisfaction. A TMS can also be used standalone or on a unified platform of supply chain software solutions for

Transportation Management Industry Use Cases

Transportation management systems are most often used by industries and enterprise businesses that need to ship and transport goods frequently or daily to secure profits. These industries include:

- Government agencies

A few examples of how a TMS optimizes the flow of goods include businesses such as grocers and pharmaceutical companies relying on accurate and speedy delivery of product to ensure reduced spoilage and temperature-sensitive goods arrive at their destination in promptly.

Omnichannel and ecommerce retail businesses also rely on TMS to provide fulfillment of purchased items to a variety of end destinations based on where the customer would like to retrieve the purchased item — in-store, ship-from-store, direct shipment to a customer’s home, etc. Retailers also rely on shipments throughout the retail network to fulfill a customer request for an item to be delivered to the closest store location for BOPIS (Buy online, pickup in-store).

Further, government agencies often require logistics services from third-party vendors or carrier services to provide aid in life-threatening emergencies.

Wholesale suppliers and manufacturers utilize TMS to solve bulk supply level capacity constraints and to protect their business from digital competition with direct-to-consumer experiences that deliver products on time, in full, and via the most sustainable route traveled.

Manhattan's TMS Solves Specific Supply Chain Needs (Case Studies)

Manhattan’s transportation management solutions enable our customers from all over the globe to navigate the logistics and supply chain landscape effectively, profitably, and seamlessly, with real-time insights and data that optimize the product journey. Here are a few of our customer success stories that detail noticeable results achieved with our industry-leading transportation management solution capabilities.

Giant Eagle

Giant Eagle optimized routes for its fleet of 340 drivers with Manhattan’s TMS, leading to an 8% reduction in empty miles and a 7.7% reduction in total miles.

Goya Food

Goya Foods combined Manhattan’s WMS and TMS to unify inbound and outbound distribution, resulting in seamless transportation workflows.

John Christner Trucking

John Christner Trucking selected Manhattan Carrier to solve two main challenges: maintaining high customer service levels and balancing drivers and equipment productivity while remaining compliant with Hours of Service (HOS) regulations. Learn how JCT recovered lost productivity and profitability with Manhattan via a reduction in deadhead miles, an 8% boost in seated truck count, a 1.8% increase in miles driven, and ROI achieved within one month post-implementation.

TMS Functionalities

TMS software is used by businesses across the globe who are looking to cut down on logistics costs and delivery times by transporting product in the most optimal way possible.

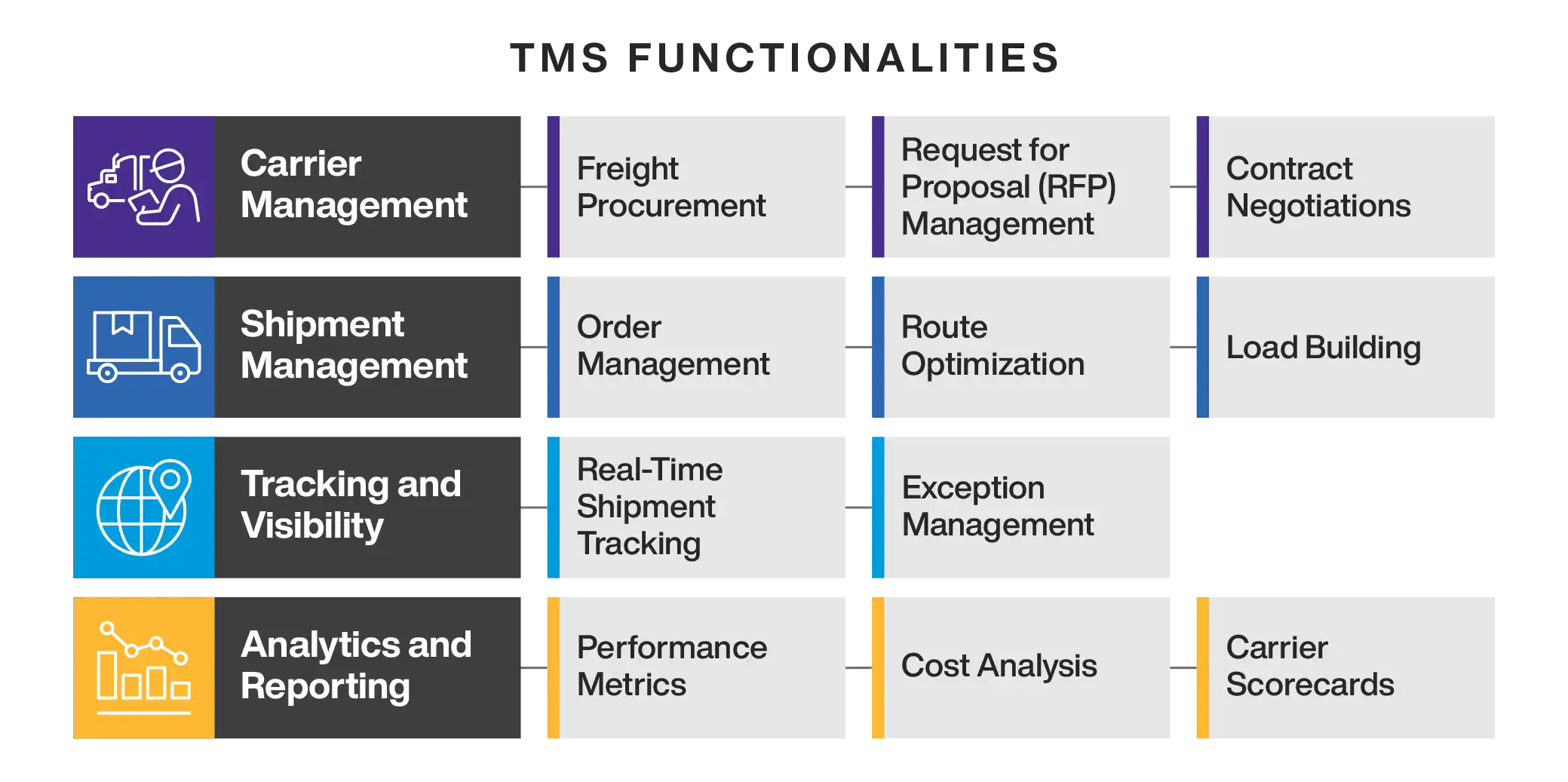

This is accomplished through advanced, modern TMS functionalities that include carrier management, shipment management, tracking and visibility, analytics and reporting, and integration of other systems in a unified platform.

Manhattan Active Transportation Management (TM) ranked among the three highest-rated solutions in Level 3, Level 4, and Level 5 complexity use cases in Gartner’s Critical Capabilities for Transportation Management Systems report.

Carrier Management

Enables businesses to manage, oversee, and optimize carriers and shipment providers and allows shippers to work directly and more effectively with service providers to improve execution. Features included in carrier management solutions are:

Freight Procurement

Freight procurement strategically finds the most optimal way to transport goods to improve levels of efficiency and productivity while simultaneously reducing transportation costs and being 100 percent compliant with government legislation.

Manhattan Active® Transportation Management features fleet management to help users manage transportation demands by aligning all transportation resources to drive new levels of efficiencies, safety and compliance. It uses the most advanced machine learning science to recommend routes, drivers, and assets automatically.

Request for Proposal (RFP) Management

RFP management features found in carrier management solutions match the right 3PLs to shippers based on business and logistic service needs.

Contract Negotiations

Carrier management helps assist with contract negotiations between a carrier and dispatcher ensuring the right detailed information is included in a legally binding document, typically describing roles and expectations from each party.

Shipment Management

Shipment management is one of the key functionalities of a TMS as it enables capabilities such as order management and tracking, route optimization, and load building.

Order Management (OMS)

Order management is a vital component of effective transportation management as it optimizes and ensures each order is being transported in the right place and ideal time through tracking and managing the lifecycle of an order from start to finish. An OMS and TMS integrated together on a unified platform ensures service level agreements, delivery dates, and order fulfillment are executed efficiently and profitably.

Route Optimization

TMS route optimization calculates the ideal path for carriers and shippers to take to reach a destination. The best route optimization components of a TMS reduce miles traveled to lower energy consumption and emissions and optimize inbound, outbound, interfacility, and backhaul coordination.

Load Building

Load building strategically handles product loads to maximize space utilization within a carrier container. The resulting increase in weight and volume utilization also contributes to lowered energy consumption and emissions.

Tracking and Visibility

Tracking and visibility features within a TMS enable users to unveil a bird’s eye view of the entire transportation network with capabilities that include real-time shipment tracking and exception management.

Real-Time Shipment Tracking

Tracking of shipments in real-time provides instant notifications and details of happenings of whichever status the shipment is currently in including before, during, and after the transportation of goods. The right TMS considers all route factors in real time and adjusts plan parameters to opportunely choose the right stops for carriers to make, increasing shipment efficiency.

Exception Management

Exception management alerts users when irregularities or unplanned instances occur during transporting and provides quick solves to these exceptions before they turn into disruptions.

Analytics and Reporting

Analytics and reporting play a crucial role in how modern TMS solutions operate by providing actionable insights to highlight areas or holes in the transportation network that need to be more efficient, and by leveraging data to maximize productivity, including performance metrics, cost analysis, and carrier scorecards.

Performance Metrics

Performance metrics — including speed of delivery, dependability, capacity, and costs — allow users to monitor carrier performance.

Cost Analysis

Cost analysis highlights expenditures in the transportation network and areas where costs can be reduced or even eliminated entirely by more efficient processes.

Carrier Scorecards

Carrier scorecards provide an overview of transportation carriers, evaluating performance metrics to assess which carriers to choose to tailor to specific transportation network needs.

Integration/Unification with Other Systems

Integrating TMS with other supply chain planning and execution systems — including warehouse management (WMS), labor management, order management, demand forecasting, and others — provides significant technological benefits that optimize the flow of goods in and out of the entire supply chain process.

When systems are unified on a cloud-native platform, they can share real-time data, receive upgrades automatically without disrupting day-to-day workflows, develop holistic planning, and can be continuously optimized to fit changing business needs. Users gain total control over supply, demand, resources, and shipments. Capabilities that come with unified systems include seamless added capacity, automatic labor adjustment to match inbound arrivals, and order changes that can be made up until the last shipment leaves the dock.

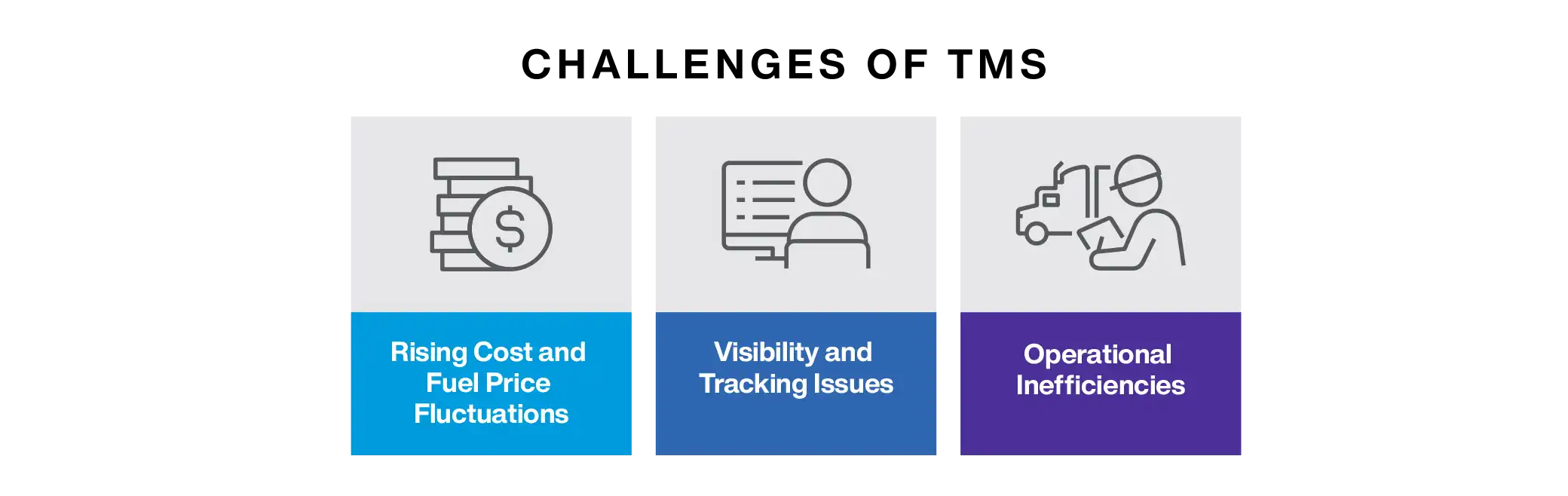

Challenges of TMS

The challenges that arise from transportation management when addressed via legacy or siloed transportation management systems include:

Rising Cost and Fuel Price Fluctuations

Rising costs and fuel price fluctuations can occur for several reasons: inflation, supply chain disruptions, pandemics, geo-political issues, and more. Transportation managers also may struggle to keep costs under control due to factors like rising fuel prices, tolls, and carrier rate volatility. If a business is operating a legacy or old TMS that does not optimize transportation management the way other companies are, these challenges could result in a loss of profits and can leave them scrambling to catch up to competitors.

Visibility and Tracking Issues

Without the necessary visibility and tracking solution capabilities, transportation management faces possible order inaccuracies, unmet delivery time and service level agreements, and lost or mismanaged inventory and carrier capacity usage, all resulting in lower customer satisfaction. Difficulty in real-time tracking of shipments across various modes of transport (truck, rail, air, or sea) can lead to delays, exceptions, and poor customer experience.

Operational Inefficiencies

Modern and cloud-native transportation management systems automate processes throughout the transportation and supply chain network, allowing them to be more agile and efficient. Manual processes in route planning, load building, carrier selection, and documentation lead to wasted time, errors, and inefficient utilization of resources.

Benefits of TMS

The benefits of leveraging TMS — especially one that is cloud native and unified with other supply chain solutions — to optimize the flow of goods within a supply chain network include:

Optimization of Routes Traveled and Carrier Loads

TMS solution capabilities can reduce miles on routes traveled by unveiling opportunities for the most optimal stops and fuel-up stations and can optimize carrier loads to maximize capacity efficiently, effectively saving shipping costs.

Real-Time Visibility of Entire Transportation Network

Users of modern TMS gain better visibility by tracking all shipments moving within the transportation network and real-time insights into data on traffic, capacity, and market rates.

Coordination of Fleets

TMS solutions can provide fleet management that balances fleet resources to maximize the usage of drivers and vehicles.

Automation Provides Compliance Assurance, Cost Reduction, and Increased Efficiency

Automated TMS capabilities can find the best way to improve the levels of efficiency and productivity, reduce overall transportation costs, and remain 100 percent compliant with government legislation and regulations.

Improved Planning

Modern TMS solutions can optimize planning for transportation managers by configuring scenarios to see probable outcomes from pending changes and demand spikes, automating shipment variance detection and resolution to reduce dead space in trailers, and leveraging historic and forecasted data for improved bids.

What are the Different Types of TMS?

There are different types of TMS offerings available on the market. Businesses must assess these different TMS solutions to choose the right one that fits specific organizational and supply chain needs. The various types of TMS solutions available are:

Cloud-Based TMS

A cloud-based TMS enables businesses of various sizes to run transportation management software applications originally designed to run on a local server in a cloud environment via the Internet. This reduces physical infrastructure and enables applications to be accessed from remote locations, increasing agility and scalability.

On-Premise TMS

An on-premise TMS relies on physical servers on location to oversee a business’s transportation management. These may be homegrown, built from scratch, or purchased from a software provider and customized to fit specific organizational needs.

Standalone TMS

A standalone TMS solely focuses on the transportation side of supply chain logistics and is often used by shippers and carrier service providers. Depending on the business needs, a standalone TMS may be all that is needed, but larger supply chain networks suffer from a lack of visibility, integration, shared data, and overall system unification with just a standalone TMS.

Integrated TMS

An integrated TMS, unified with other supply chain software solutions on a singular platform provides a link between distribution and transportation for optimal efficiency. Larger or enterprise businesses utilize integrated TMS solutions to unify transportation, warehouse, labor, and order management to break down the barriers of inbound/outbound workflows.

Depending on various factors such as supply chain size, industry, and complexity, each type of TMS provides its own set of beneficial outcomes to improve transportation management.

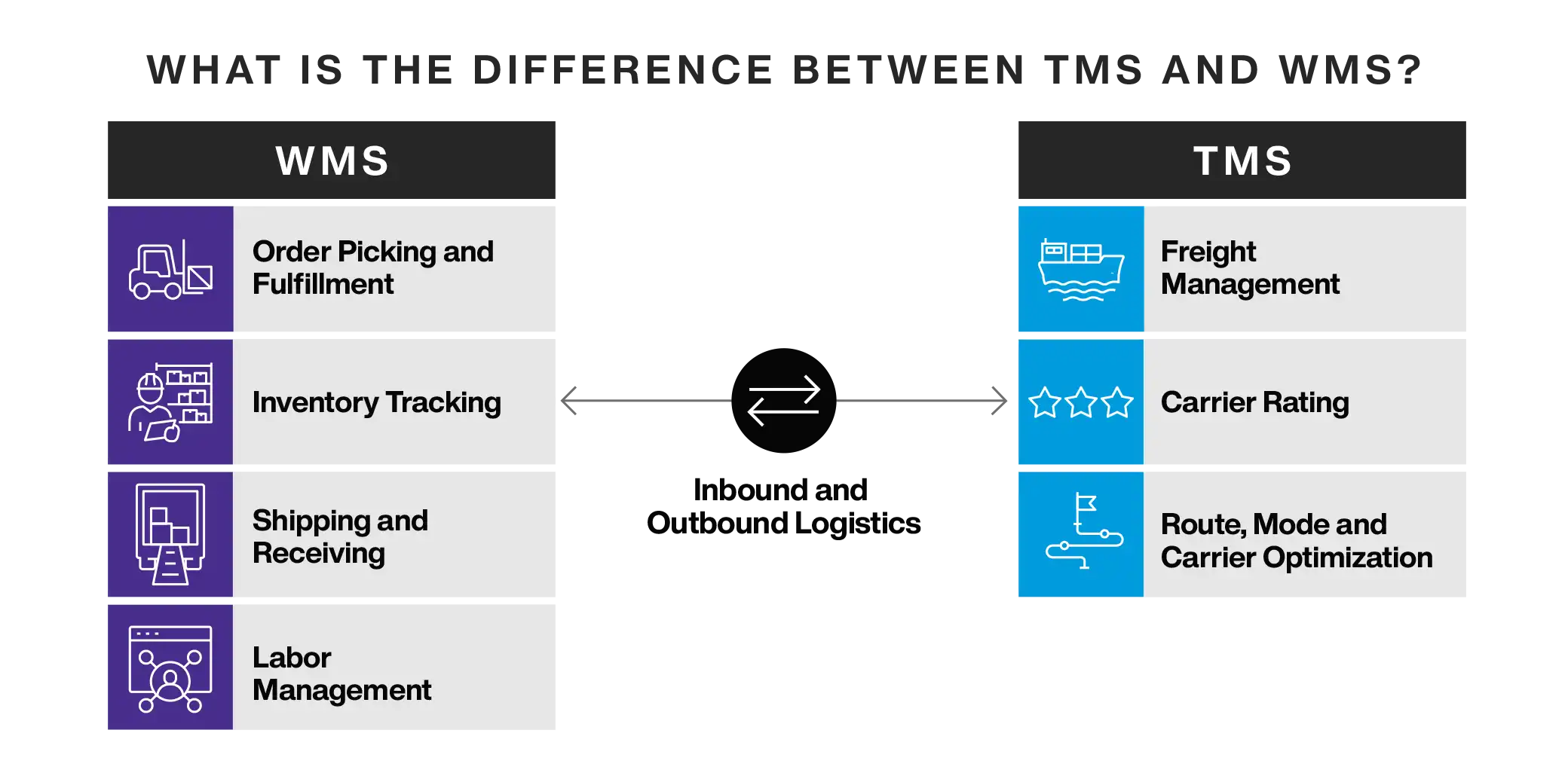

What is the Difference Between TMS and WMS?

The difference between a TMS and a WMS is TMS oversees the logistics and transportation management side of supply chain operations and WMS handles the distribution side. When the two systems do not communicate with one another, there are blind spots and gaps in efficiency, and businesses that are driving legacy versions of each system, siloed from one another, are missing out on opportunities for supply chain growth and optimization.

However, when both are working symbiotically on a unified platform, the full potential of system capabilities can be reached by unlocking end-to-end supply chain agility, visibility, and collaboration.

To work at maximum efficiency, the best TMS software solutions also live in a cloud environment as part of a single unified platform that brings together every aspect of distribution and transportation, unifying supply chain operations.

Manhattan Active Supply Chain, a single app for complete command and control of all distribution, labor, automation, and transportation, brings together inbound and outbound workflows by having transportation, warehouse, and labor management systems work in a symbiotic supply chain together, instead of separated from each other. This enables the ability to accept order changes up until the very last moment of loading and allows adjustments to warehouse receiving labor staffing based upon real-time inbound transportation activity.

How to Implement a TMS

Depending on business size and project scale, implementation of a TMS can take anywhere from a few months to over six months. After selecting the right TMS for specific business needs, implementation often consists of various stages that include a kickoff or initiation meeting, design, build, preparation, testing, deployment, and support from the TMS provider.

What is the Future of Transportation Management?

Emerging trends in transportation management technology are making it easier than ever to execute logistics and transportation processes profitably and sustainably. Artificial Intelligence (AI) has been rapidly advancing with optimized planning and execution via generative AI that can automate workflows, uncover hidden insights, and accelerate innovation. AI assistants can analyze key variables and constraints in real time, providing instantaneous insights and recommendations on opportunities for optimization.

Chatbot and user interactions within applications are being transformed with the integration of generative AI solutions thanks to intuitive conversational interfaces built on sophisticated LLMs.

In fact, according to Gartner, “Generative AI is primed to make an increasingly strong impact on enterprises over the next five years and 40% of enterprise applications will have embedded conversational AI by 2024.”

Technological sustainably efforts have also made strides in producing more sustainable transportation practices through improved modal shifts for the most optimal route and method of transportation and technology capabilities that result in carbon footprint reduction.

Manhattan Active® Transportation Management allows companies to reduce the environmental impact of computing via the introduction of a modern, microservices-based architecture, resulting in:

- Higher levels of utilization

- Lower power consumption

- More efficient operations

- Reduction in carbon footprint

What are the Attributes of the Best TMS?

The best TMS software, such as Manhattan Active® Transportation Management System, is built with 100% microservices and is cloud native, which enables the software to be agile, extended, and can take advantage of seamless upgrades. It is equipped with state-of-the-art capabilities that calculate and consider numerous transportation factors through applied intelligence, which utilizes real-time distribution planning and optimization for better, faster operational decisions.

It features capabilities such as continuous optimization, unified logistics control, fleet management, modeling, procurement, and carrier management — all of which make the lives of your supply chain workers that much easier with automated, flexible solutions and keep your customers satisfied. The results produce transportation network savings across the board.

To work at maximum efficiency, however, the best TMS software solutions also live in a cloud environment as part of a single unified platform that brings together every aspect of distribution and transportation, unifying supply chain operations.

Deliver On Your Promise to Customers

Get in touch with the Manhattan team to see how we can help.

Manhattan Leads the Gartner Magic Quadrant and Critical Capabilities for TMS

A Recognized Leader

Manhattan is a Leader in the 2025 Gartner® Magic Quadrant™ for Transportation Management Systems and Manhattan Active Transportation Management (TM) is the only cloud-native solution in the Leader Quadrant. Gartner’s recognition of Manhattan as a Leader in the Magic Quadrant and the strong performance of our TMS across Level 3, 4, and 5 complexity use cases in the Critical Capabilities report reflect both our technology leadership and our performance in driving innovation, customer success, and supply chain execution excellence.

Transportation Management FAQs

A transportation management system (TMS) is a supply chain software solution that enables enterprise-wide management, optimization, planning, and execution of logistics services for transporting goods in both inbound and outbound movement.

The key benefits users gain from TMS include optimization of routes traveled and carrier loads, real-time visibility of an entire transportation network, coordination of fleets by balancing and allocating resources, automation that provides compliance assurance, cost reduction, increased efficiency, and improved transportation planning.

The phases of a transportation management system are information gathering, transportation planning, transportation execution, and inventory and performance management optimization.

The challenges that arise from transportation management when addressed via legacy or siloed transportation management systems consist of rising costs and fuel consumption, visibility and tracking, and operational inefficiencies.

The difference between a TMS and a WMS is TMS oversees the logistics and transportation management side of supply chain operations and WMS handles the distribution side.

Having TMS and WMS working symbiotically in a unified platform unlocks end-to-end supply chain agility, visibility, and collaboration. This combination brings together every aspect of distribution and transportation, unifying supply chain inbound and outbound workflows.

Related Articles

See how Manhattan’s unified cloud-native platform can unlock unprecedented agility and unification for your supply chain or logistics operations.

7X Gartner Magic Quadrant Leader

Manhattan Active® Transportation Management is the only cloud native solution in the Leader Quadrant. Read the report to learn which TMS provider is best suited to manage disruptions and mitigate risk in your supply chain ecosystem.

Related TMS Articles

Making the Case for TMS: Driving Supply Chain ROI

Read here how a TMS can drive supply chain ROI.

TMS ROICustomer Success Story with Hy-Vee

Discover the impact on efficiency, agility, and customer satisfaction.

TMS Case Study