Power Stores With RFID

Strengthen store operations to support and scale omnichannel commerce reliably with store inventory and fulfillment processes powered by RFID.

Raise Store Inventory Accuracy

Store inventory becomes significantly more accurate when tracked with RFID, improving customer experiences and retailer profitability. Learn More

Accelerate Store Fulfillment

RFID accelerates and scales stores' ability to consistently meet customer store pickup and delivery expectations. Learn More

Lower Store Operations Effort

RFID makes store front- and back-office work more efficient, freeing associates to engage with shoppers and reducing operational costs. Learn More

Make Store Inventory Highly Reliable

Significantly improve store inventory accuracy to satisfy customer demand and support purchases in any sales channel reliably.

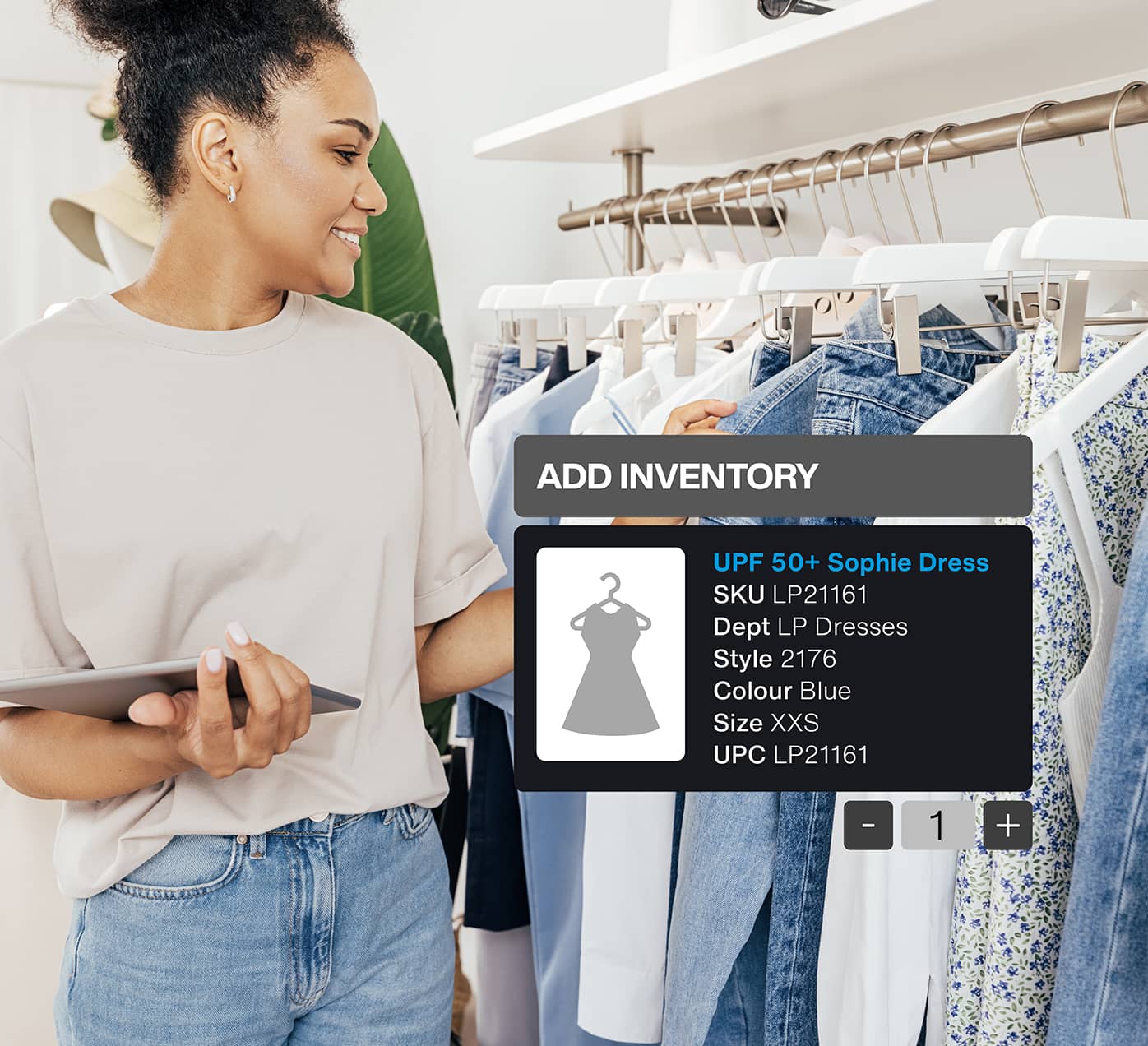

Strengthen Store Inventory Management

Improve the precision and speed of store inventory management processes, increasing store inventory availability accuracy. Learn More

Carefully Manage Store Inventory Flows

Secure timely and precise inbound receiving and outbound transfer processes that are essential for high store inventory accuracy. Learn More

Amplify Store Inventory Visibility

Reliably share store inventory availability across all sales channels to elevate the omnichannel retail experience. Learn More

Transform Store Fulfillment

Streamline and fortify store fulfillment processes to meet growing demand, control costs, and always meet customer expectations.

Engage and Enable Store Associates

Store associates are at the center of delivering a reliable store fulfillment experience. Enable them with the tools to excel at their work. Learn More

Lift Store Fulfillment Precision

Bring distribution center precision and efficiency to store fulfillment, ensuring stores consistently keep customer promises. Learn More

Provide an Exceptional Pickup Experience

Delight customers with exceptional service during in-store or curbside order pickups. Learn More

Drive Store Fulfillment Excellence

Use unique insight-driven techniques to drive the store fulfillment excellence that fosters competitive differentiation.

Leverage Goals and Gamification

Encourage fulfillment performance improvement through goal setting and results gamification among stores. Learn More

Employ Peer Comparative Insights

Compare store fulfillment performance against industry peers to drive meaningful performance improvements. Learn More